Proven Corrosion Barrier

Superior performance & longer service for:

- Oil and gas producing wells

- Offshore platforms

- Onshore work-overs

- Injection Wells

- Salt water disposal systems

- Chemical disposal wells

- Sour Gas service

- Geo Thermal wells

- Carbon Capture & Storage (CCS)

Time Tested Technology

Maxtube’s DUOLINE® products offer an unsurpassed record for prevention of corrosion in very demanding conditions. Protecting oilfield tubulars from corrosion since 1964, more than 100 million feet of DUOLINE® glass reinforced epoxy (GRE) lined tubing has been installed worldwide.

Global Reach

Whether your operations are in the North Sea, West Texas, North Slope, South America, Middle East, Asia, or Australia, Maxtube and our affiliates have experts ready to help solve your corrosion problems.

DUOLINE® D-20

DUOLINE® 20, manufactured by Maxtube’s Duoline Technologies, is a filament-wound Glass-Reinforced Epoxy (GRE) liner which is installed to OCTG in corrosive service. It is widely accepted that GRE lining is a more robust alternative to internal plastic coating. DUOLINE® 20 is a very effective corrosion barrier with a long history of tubular protection in a variety of offshore and landbased applications.

Where Will You Benefit From Using DUOLINE® 20?

- 250°F working temp

- CO2 /Water injection/disposal

- Chemical disposal

- Gas Production

- API or Premium Thread Compatibility

Why Use DUOLINE® 20?

- Lower cost alternative to CRA

- Durable/Long lasting corrosion protection

- Most complete corrosion package

- Most abrasive resistant lining system available

- Proven field history

The workhorse of the DUOLINE® lining systems. DUOLINE® 20, developed in 1971, is targeted for more demanding corrosive downhole environments. The DUOLINE® 20 system has a proven track record in a great number of demanding environments including water injection, CO2 injection, gas production, gas-lifted oil production and chemical disposal wells, onshore and offshore. DUOLINE® 20 has an outstanding performance history in environments containing produced fluids and gasses with CO2 and H2S. DUOLINE® 20 has successfully prevented corrosion in gas production wells with BHT as high as 292°F (144°C), and is typically used in water injection and gas production service up to 284°F (140°C) dependent on well conditions.

DUOLINE® 20 has proven to be the most abrasion resistant coating or lining product in downhole wireline trials in deviated wells. It is acid compatible, impact resistant, resistant to gas service failures common to other coatings or linings, premium connection compatible, chemically resistant and tolerant to common tension and bending loads. Quite simply, DUOLINE® 20 offers unsurpassed corrosion protection by a lining system.

DUOLINE® 10-PE

DUOLINE® 10-PE, is a lining system which utilizes a heavy wall high density polyethylene liner and is targeted for use in specific applications for reduction of tubing corrosion in low temperature & low pressure environments. DUOLINE® 10-PE is especially suited for shallow water injection well tubing where corrosive water is injected and performs within a temperature range of -20°F + 160°F.

DUOLINE® 10 BEATING THE HIGH COST OF CORROSION

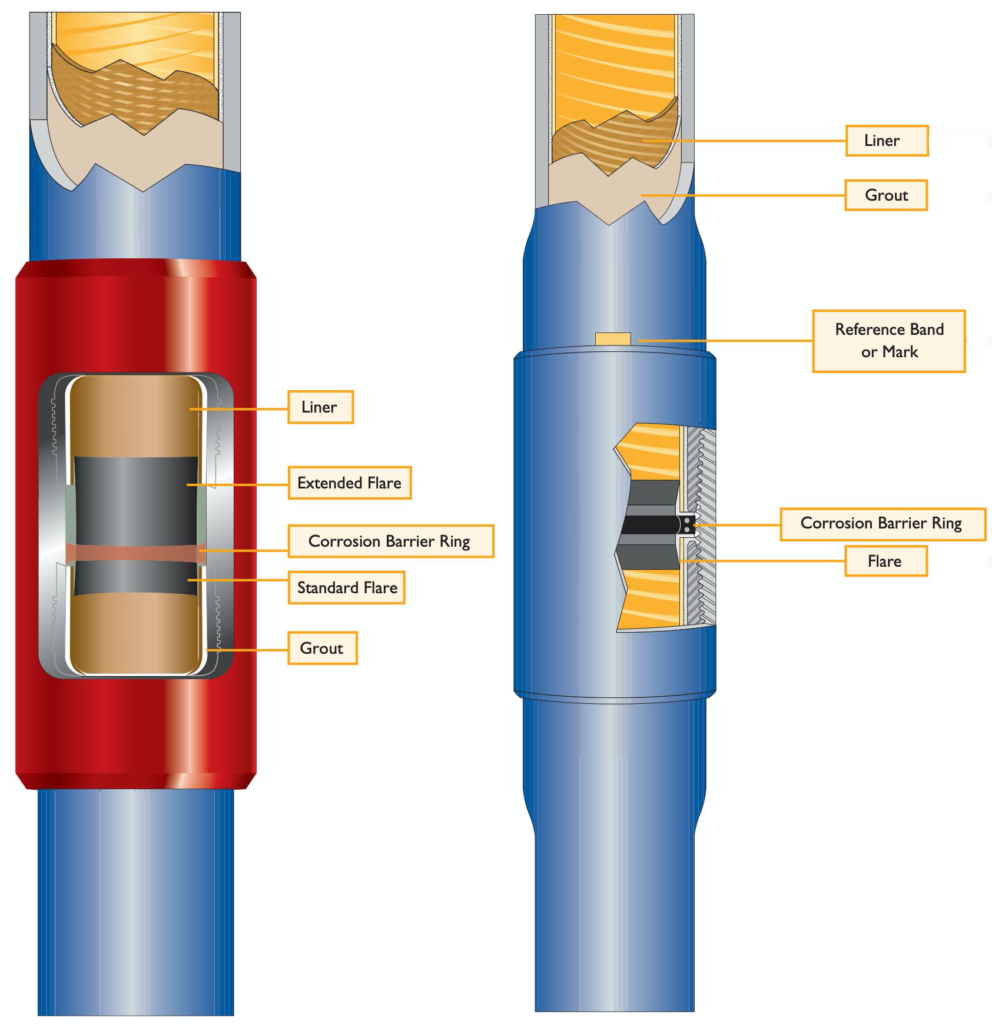

DUOLINE® 10 is part of the unique Duoline process of inserting liner tubes into steel pipe and filling the annular space with a special cement applied with pressure. Ends are flared back so that both ends are flat and can be protected in the collar. Thus, the interior of the pipe is essentially inert to common acids and corrosive fluids.

DUOLINE® 10 also provides reliable joint protection. The lining is positioned on the pin and collar end of threaded pipe so that the collar is protected from corrosion when corrosion barrier rings are used. Smoothness is ensured by the fact that the interior of the liner is unaltered during the lining process, thereby retaining the ‘C’ factor of 150.

RiceWrap by Duoline

External Corrosion Control

RICEWRAP® is a protective wrap of fiberglass epoxy externally applied and bonded to steel pipe.

Recommended For:

- External corrosion protection on down hole tubing.

- Use between injection mandrels and/or packers in multi-zone completions.

Specifications:

- Material: Filament wound fiberglass-epoxy.

- Thickness: Nominal thickness 0.100″

- Working Temperature: -29°C (-20°F) to 121°C (250°F).

- Sizes: 2-3/8″ through 7.0″ OD.

- Consult Duoline Technologies for custom applications.

Installation:

- An external corrosion barrier ring is used to protect the threads of the connection.

- External corrosion barrier ring is compressed during field makeup.

- The corrosion barrier ring provides for hassle-free break-out and reassembly in the field.

- Epoxy kit is available to repair installation and handling damage.

Duoline “DL-Ring”

A unique corrosion barrier system enabling placement of GRE internal liners inside any shoulder-to-shoulder premium thread without the need for a special coupling!

THE CHALLENGE:

To provide superior internal corrosion protection using a Glass-Reinforced-Epoxy (GRE) lining system with any unmodified free-issue premium threaded tubing or casing.

THE SOLUTION: IN TWO EFFECTIVE STEPS:

1. Use DUOLINE® from Duoline Technologies: a premium internal corrosion resistant lining system for oilfield steel tubing and line pipe. DUOLINE® is proven to be wireline abrasion and chemically corrosion resistant in both controlled laboratory testing and through successful performance in more than 75,000,000 feet of downhole application.

2. Use Duoline Technologies new DL-RING patent pending connection technology that permits the lining system to accommodate any proprietary Premium Connection.

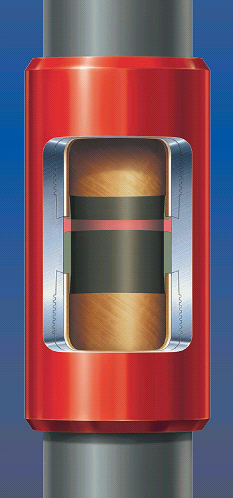

HOW DOES THE DL-RING WORK?

Two DL-flares place the DL-CBR in compression during field make-up.

The unique concept and material composition has been used extensively and successfully in downhole completions with DUOLINE® tubing in numerous other ‘FGL’ versions of unmodified premium and API connections.

Portable Lining Unit

With the creation of the MaxTube Portable Lining Unit, MaxTube have made the lining process completely mobile. Whereas other coatings and linings can only be applied/inserted at specific/selected sites, MaxTube can carry out the lining process almost anywhere.

With 7 Portable Lining Units (PLUs) operating worldwide, MaxTube are able to mobilise a Portable Lining Unit to carry out a lining operation at the most convenient location for our customers. These include a local yard or even at a steel mill where the pipe originates.

Benefits of MaxTube’s Portable Lining Unit:

- Lining operations can be carried out in any location around the world.

- Eliminates the need for customers to transport their bare pipe to specific locations.

- Companies can use their existing pipe stock.

- Customer’s used pipe can be lined.

- Measuring 7ft x 6ft x 8ft high, the unit fits into a standard 20 ft. shipping container and can be easily shipped by air, sea and/or by road to the desired location.

Field Services

Protect your investment in steel tubing and DUOLINE with supervision by a trained DUOLINE Service Technician any time you plan to run, pull, or repair DUOLINE tubing. Clients who routinely use these technicians to supervise the DUOLINE installation typically enjoy a trouble free life for their tubing strings.

Some of the services offered by MaxTube’s trained field Service Technicians include:

- Running/ Pulling DUOLINE products in the well

- Field repair of DUOLINE products

- Inspection of DUOLINE stock or used DUOLINE joints

MaxTube maintains a staff of DUOLINE trained field Service Technicians who can be dispatched to supervise DUOLINE installation, repair or running. For further information please use our General Enquiry Form or for product selection please complete the DUOLINE Selection Form.

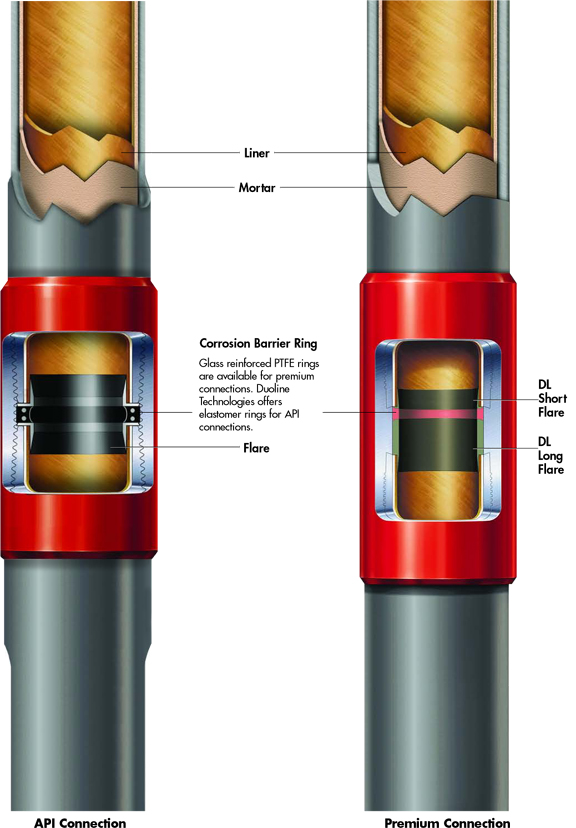

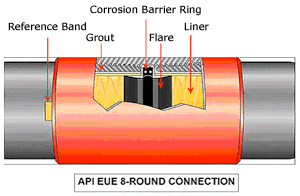

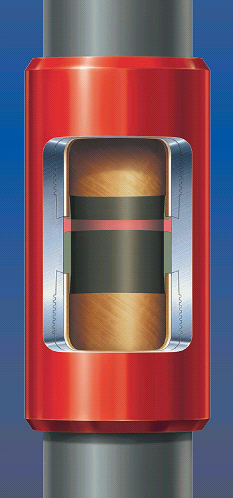

Corrosion Barrier Rings

Duoline Technologies Corrosion Barrier Rings, for use with API Connections, complete the corrosion protection package when used with DUOLINE. The Corrosion Barrier Rings (CBR’s) are offered in two different oil resistant elastomers. The PC-CBR (nitrile rubber) is recommended for typical produced oilfield fluid applications. However, if concentrations of CO2 are significant, the HP-CBR (modified nitrile polymer) should be considered. The HP-CBR is a higher strength material and is more tolerant to blistering and explosive decompression associated with elastomers in CO2 service. All DUOLINE Corrosion Barrier Rings are reinforced with spring steel wire, thus insuring the CBR will stay in place during pressure cycles.

Glass reinforced PTFE Corrosion Barrier Rings are available for specifically designed Premium Connections from MaxTube.

For further information please use our General Enquiry Form or for product selection please complete the DUOLINE Selection Form.

For further information please use our General Enquiry Form or for product selection please complete the DUOLINE Selection Form.

API Connections

- API connections used where conditions or design requirements permit their use

- API connections employ the DUOLINE TECHNOLOGY manufactured corrosion barrier ring (CBR), which has over 35 year history

- API EUE 8-Round Connection

- New and Used Tubing can both be lined

- Thread condition should meet API Standards

- Driftability of used tubing is critical

- End User selects used steel grade (EMI Color Code and/or hydrostatic testing requirements)

- Packers and Accessories can also be lined

Sizes, Weights & Lengths Available in API connections

- 2-1/16″ 3.25 # IJ 10rd

- 2-3/8″ 4.7 # EUE 8rd & 4.6 # NU 10rd – 32.5’ max length

- 2-7/8″ 6.5 # EUE 8rd & 6.4 # NU 10rd -32.5’ max length

- 3-1/2″ 9.3 # EUE 8rd & 9.2 # NU 10rd – 32.5’ max length

- 4-1/2″ 12.75 EUE 8rd & 11.6 LTC/STC 8rd – 40.0’ max length

- 5-1/2″ 17 # & 20 # LTC/STC 8rd, Buttress – 43.5’ max length

- 7″ 23, 26, 29, 32 # LTC/STC 8rd, Buttress – 43.5’ max length

- *LTC & STC casing threads have demonstrated limitations

Premium Connections

- Premium connections used where conditions or design requires higher performance.

- Premium connections employ a PTFE ‘Teflon’ CBR.

- Many premium connections available, Key Issue, the connection must accommodate a CBR.

- Special Threading Requirements.

- T&C tubulars delivered to MaxTube pin-by-pin, couplings loose.

- Special consideration given to lined tubing to unlined accessories, Rule: lined pin mates unlined accessory box with DUOLINE – CBR groove.

Tubing Accessories

Lined Accessories:

MaxTube can install DUOLINE linings inside tubing accessories such as pup joints, tubing nipples, cross-over nipples, swage nipples & packer mandrels – providing for DUOLINE protection from “Top – to -Bottom” in your Tubing String Design.

Adaptor Rings:

These hard plastic molded rings are specially designed to permit CBR compression when mating an unlined EUE 8-round accessory, such as a packer to a lined DUOLINE joint.

MAJOR USERS INCLUDE: AIOC • AL KHAJI JOINT OPERATIONS • ANADARKO • HESS • BHP • BP • BRITISH GAS • CANADIAN NATIONAL RESOURCES • CHEVRON • CONOCO PHILIPS • ENI • EXXONMOBIL • EQUINOR • INA • KHALDA PETROLEUM • KUWAIT OIL COMPANY • OCCIDENTAL • PERTAMINA EP • PETROBRAS • PETROLEUM DEVELOPMENT OMAN • QARUN PETROLEUM • QATAR PETROLEUM • SAKHALIN ENERGY INVESTMENTS COMPANY • SAUDI ARAMCO • SHELL • TOTAL • TULLOW • TAQA